Using biotechnology to transform agro-food industry by-products into biopolymers for circular and regenerated cellulose fibres in textile fabrication processes.

At a glance

- The project connects an interdisciplinary research group from biotechnology, materials science, engineering, design and lifecycle analysis.

- This research proposes to produce materials from waste to reduce the environmental footprint of textiles.

- We are seeking to develop new routes for the development of localised cellulosic fibre production.

Key details

More information

The challenge

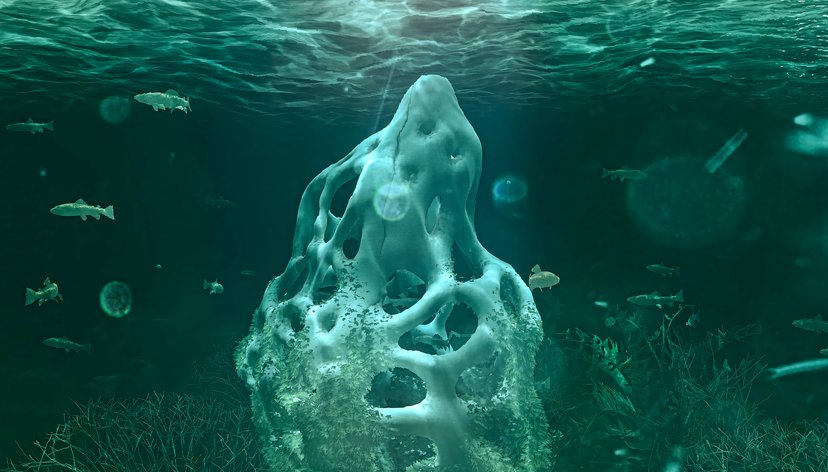

The challenge is to explore the potential of using cellulose from agricultural by-products and the biological fraction of municipal solid waste as a replacement to cellulose that is currently derived from trees for semi-synthetic textile fibres such as viscose and lyocell. The work involves maximising the productivity of biotechnological systems for producing cellulose, trialling the production of viscose-like regenerated fibres from our cellulose, and producing and testing textiles made from these fibres.

Planned outcomes

The project is led by the Centre for Novel Agricultural Products at the University of York, which will convert wastes into sugars for bacterial fermentation into cellulose. The University of Leeds will lead to the trials of regenerated cellulose fibre production in sustainable and non-toxic regeneration technologies. Once these fibres are produced, they will be introduced into a range of textile fabrication processes in the Sustainable Future Materials theme of the Materials Science Research Centre. The proposed work will aim to increase process efficiency and to generate data to carry out a techno-economic analysis to assess the commercial viability of this novel process for textile manufacturing. MSRC Visiting Professor Phil Purnell will assess the environmental impacts of making textiles in this way using a life cycle analysis.

Team

Ask a question

Get in touch to find out more about our research projects.

[email protected]